CNC Machining

Quality CNC Milling Service

BP Prototype provides a reliable and cost-effective CNC milling service. Equipped with advanced, automated CNC lathes, we specialize in handling complex part machining with precision. Whether your project requires 3-axis or 5-axis machining, BP Prototype delivers high-quality custom CNC milled parts tailored to your specifications. Our milling services support both prototyping and low-volume manufacturing needs, catering to industries worldwide. We work with a diverse range of materials, including metals, plastic polymers, wood, and other prototype materials, ensuring flexibility and versatility for your CNC milling projects.

Popular CNC Milling Materials and Finishing

- Metal

Aluminum( Grades like 6061, 6063, and 7075 are frequently milled.)

Steel( Includes carbon steel, stainless steel, and alloy steel.)

Brass( Preferred for plumbing components, fittings, and electrical applications.)

Titanium( Lightweight, strong, and highly resistant to corrosion.)

Copper( Excellent electrical and thermal conductivity.)

Magnesium( Extremely lightweight and machinable.)

Tool Steel( Ideal for cutting tools, dies, and molds.)

Zinc

Each metal is chosen based on project requirements, including strength, weight, machinability, and application-specific properties.

2. Plastic

ABS ( Acrylonitrile Butadiene Styrene)

Acrylic ( PMMA)

Transparent and lightweight.

Nylon ( Polyamide)

Delrin ( Acetal or POM)

Polycarbonate ( PC)

HDPE ( High-Density Polyethylene)

PTFE ( Teflon)

PVC ( Polyvinyl Chloride)

PEEK ( Polyether Ether Ketone)

Polypropylene ( PP)

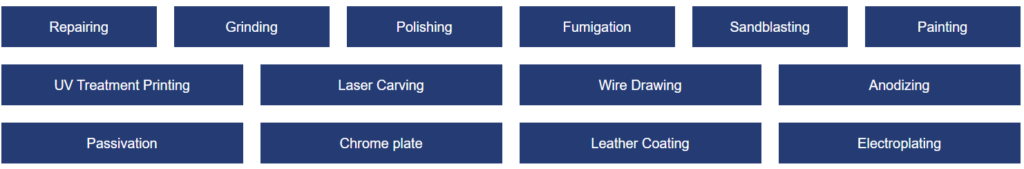

Finishing Services

In addition to machining service, we also offer various surface finishing services to make your parts have perfect outlook as your idea design. The finishing ranges from simple deburr, polish and smooth to painting, silk printing, anodizing, sand blasting, heat treatment, black anodized, nitride coating,carburizing, PVD coating,powder coating and etc.. The post-processing is to handle the parts with clean sweeping, deburring, rust-cleaning, and degreasing.